When it comes to efficient project management, the use of conex boxes has become a game changer across various industries. These versatile shipping containers are not only practical for storage but also serve as temporary workspaces or on-site offices, making them an invaluable asset to any project. Whether you're in construction, event planning, or logistics, understanding how to maximize the potential of conex boxes can lead to significant cost savings and operational efficiency.

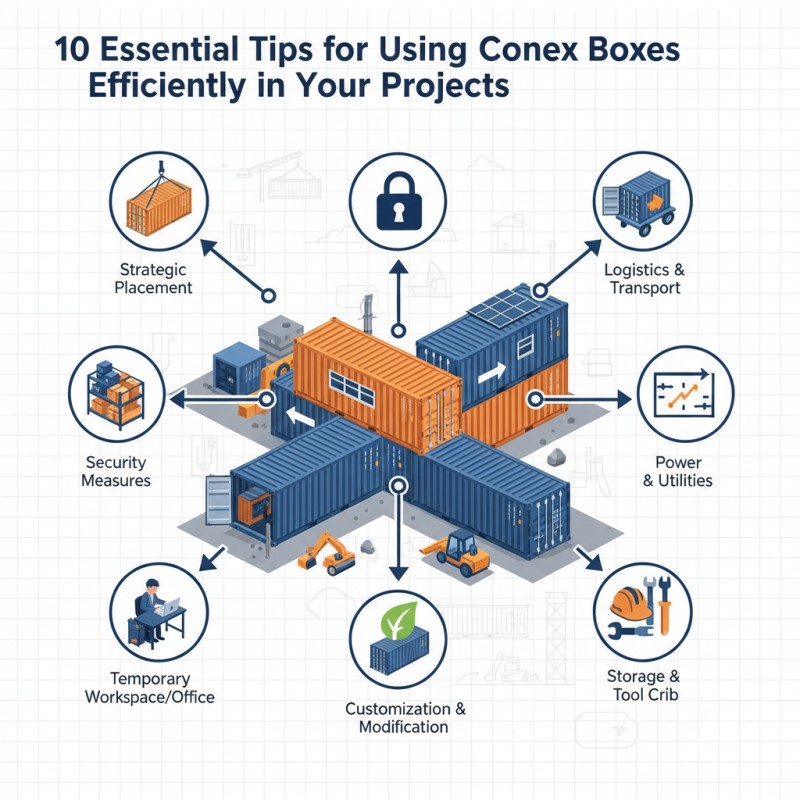

To ensure that you harness the full capabilities of conex boxes in your projects, we've compiled ten essential tips that will guide you in making the most of these multifunctional containers. From strategic placement on-site to effective organization and security measures, these insights will empower you to integrate conex boxes seamlessly into your workflow, thus enhancing productivity and streamlining your operations. By implementing these best practices, you can unlock the true potential of conex boxes, transforming them into a pivotal component of your project management strategy.

Conex boxes, also known as shipping containers, have become increasingly popular in various industries due to their versatility and durability. Constructed from robust steel, these containers are designed to withstand harsh weather conditions, making them ideal for both temporary and long-term storage solutions. Their modular design allows for easy stacking and transportation, enabling efficient use of space on job sites or during relocation. Whether used for onsite storage or as portable workspaces, Conex boxes provide a reliable structure to safeguard materials and equipment from the elements.

In addition to their physical durability, Conex boxes offer significant economic benefits. These containers are often more cost-effective than traditional construction solutions, as they can be easily repurposed and relocated without additional construction costs. The modular nature of Conex boxes also allows for creative uses, such as transforming them into offices, workshops, or even living spaces, allowing project managers to optimize their resources. Furthermore, their scalability means that as projects grow or needs change, additional containers can be added seamlessly to accommodate new requirements.

Strategic placement of conex boxes in your project can significantly enhance efficiency and functionality. According to the Portable Storage Association, inappropriate layout planning can lead to a 20% increase in operational costs due to logistical inefficiencies. Therefore, it's essential to analyze your project's specific requirements before deciding on the optimal configuration.

When planning your layout, consider proximity to work areas, access points, and resource distribution. Placing conex boxes too far from the primary work zone can hinder workflow and increase travel time for personnel. A good practice is to conduct a site survey that includes traffic flow analysis and accessibility, ensuring that the placement of your conex boxes aligns with the overall project dynamics.

Tips to remember include ensuring that each box is clearly labeled to facilitate easy identification and access. Additionally, consider using a layout that optimizes vertical space, as a recent study by Statista indicated that vertical storage solutions can save up to 30% more space in tight job sites. Keep in mind that seasonal weather variations might also affect your layout, so plan for seasonal modifications to maintain accessibility and security throughout the project duration.

| Tip Number | Tip | Description | Efficiency Impact |

|---|---|---|---|

| 1 | Assess Your Needs | Determine the purpose of using Conex boxes in your project. | High |

| 2 | Choose Strategic Locations | Identify the best spots for placing the boxes to facilitate workflow. | Medium |

| 3 | Ensure Accessibility | Place Conex boxes where they can be easily accessed by staff. | High |

| 4 | Stagger Storage | Avoid crowding by spreading boxes out to create pathways. | High |

| 5 | Label Clearly | Use clear labels to identify the contents of each box. | Medium |

| 6 | Prioritize Security | Ensure locations are secure to prevent theft or vandalism. | High |

| 7 | Use Multiple Sizes | Select different sizes based on specific needs for optimal storage. | Medium |

| 8 | Regular Maintenance | Schedule routine checks to ensure boxes are in good condition. | Medium |

| 9 | Consider Environmental Factors | Position boxes to avoid exposure to extreme weather conditions. | High |

| 10 | Plan for Expansion | Design layout with future growth and storage needs in mind. | High |

When it comes to maximizing space in your projects, Conex boxes can serve as versatile solutions for storage and organization. These robust containers offer substantial capacity and can be creatively repurposed to fit various needs. By utilizing shelves and modular storage systems within the boxes, you can transform them into efficient storage hubs. This way, not only do you make the most of the vertical space, but you also keep items organized for easy access.

One essential tip is to categorize items and invest in clear bins or labels. This practice ensures that everything has its designated space within the Conex box, making it easy to find what you need without unnecessary searching. Additionally, consider using stackable containers to maximize your storage capabilities. By making your items stackable, you can effectively use vertical space, leaving more floor area clear.

Another creative solution involves using the exterior of the Conex boxes. Adding hooks, shelves, or pegboards to the sides can provide extra space for tools or equipment, thereby expanding your storage options even further. By thinking outside the box, you enhance your project's storage potential while keeping everything organized and accessible.

When utilizing Conex boxes in various projects, prioritizing maintenance and safety is crucial to ensure these containers serve their intended purpose effectively and last for years. Regular inspections are essential; according to the Container Owners Association, nearly 30% of shipping containers do not meet safety standards due to neglect. To mitigate risks, a scheduled maintenance plan should include checking for rust, structural integrity, and the functionality of doors and locks. Proper cleaning and environmental control within the boxes can further enhance their lifespan, keeping them in serviceable condition for essential storage or transport needs.

In addition to routine inspections, safety during handling and transport must not be overlooked. The Occupational Safety and Health Administration (OSHA) emphasizes that improper handling of shipping containers accounts for a significant number of workplace injuries. Implementing guidelines for safe lifting techniques and utilizing appropriate equipment can minimize these risks. Moreover, equipping Conex boxes with safety features, such as reinforced corners and fire-resistant materials, adds an extra layer of protection for workers and goods alike. This proactive approach not only helps in maintaining the integrity of the boxes but also fosters a safer working environment for all involved in the project.

This chart highlights the essential tips for using Conex boxes efficiently in your projects, focusing on maintenance and safety care.

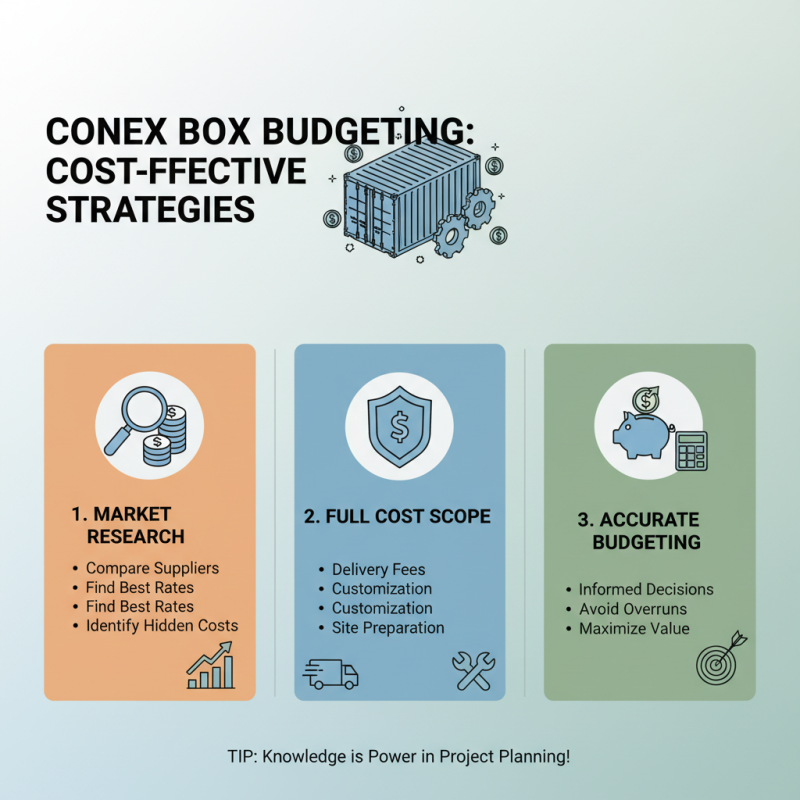

When considering the implementation of Conex boxes in your projects, budgeting plays a crucial role in ensuring cost-effectiveness. One key tip is to conduct thorough market research to compare pricing from multiple suppliers. This not only helps in identifying the best available rates but also sheds light on any hidden costs involved, such as delivery fees or additional customization expenses. Understanding the full scope of costs will allow for more accurate budgeting and better decision-making.

Another important tip for budgeting effectively is to consider the long-term value of Conex boxes in your project. While the initial investment may seem high, the durability and versatility of these boxes can lead to significant savings over time. They can be repurposed for various uses, reducing the need for additional purchases or rentals in the future. Planning for multiple uses from the outset can help justify the initial cost. Additionally, ensure to include maintenance and potential resale value in your financial calculations, as these factors can further enhance the cost effectiveness of your Conex box investment.

Are you still planning to build your shipping container home this year? How about you could save up to $5,000 in delivery costs towards your project?

With the Tiny Home Expos in Brisbane, Adelaide and Canberra in the coming months, we are offering FREE DELIVERY (*up to $5000) to each state the Expo is in, in exchange with using your project as a display at the show. Offer expires 8 weeks before each Expo and limited to ONE project per Expo ONLY so reach out to us now to secure your spot!

Enquire Now